As a service company, we have specialized in the areas of welding and testing technology as well as the training and further education of technical employees since 2011. We are now expanding our services to include manufacturing and

Assembly for the industry. We offer our customers comprehensive support in the areas of production and assembly in order to successfully implement their projects. Our experienced team and our modern

technologies guarantee the highest quality and reliability:

- Pressure vessels according to PED

- Pressureless containers

- Components for plant engineering

- Components for mechanical engineering

- Apparatus engineering

- Piping and piping components

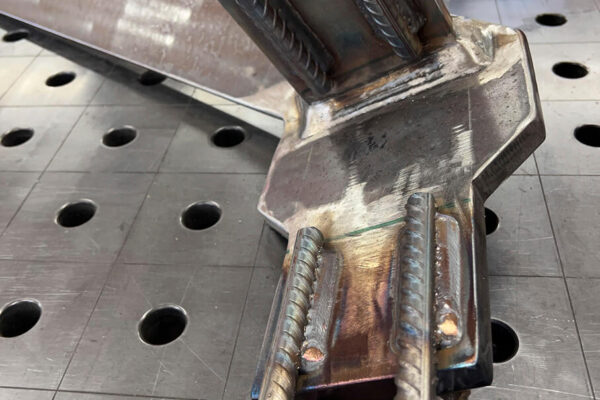

- Welding of reinforcing steel

- Stud welding

- Welding of special materials

- Special welded constructions

- Repairs to pressure equipment

- Steel construction

As a certified company with many years of experience in the field of welding and testing technology, we are your contact for these tasks. Our expertise and professionalism guarantee that every process is perfect.

is implemented without leaving anything to chance.

Our welding processes

- 135 – Metal – Active gas welding with solid wire electrode

- 136 – Metal – Active gas welding with welding powder-filled wire electrode

- 138 – Metal – Active gas welding with metal powder-filled wire electrode

- 131 – Metal – Inert gas welding with solid wire electrode

- 141 – Tungsten – Inert gas welding with solid wire, solid rod filler metal

- 783 – Drawn arc stud welding with ceramic ring or shielding gas, possible stud diameters from 13mm to 22mm

- Orbital welding for the pharmaceutical, petrochemical and food industries

- Welding of reinforcing steel in accordance with EN ISO 17660, diameter from 8mm to 40mm

Quality assurance and approvals of ARCEXPERT GmbH

- EN ISO 3834-2 comprehensive quality requirements for operation

- Certificate for provisions of §51 para. 3 Pressure Equipment Act

- Certificate AD 2000-Merkblatt HP 0

- Agreement on restamping in accordance with AD 2000 HP 0

- EN 1090-2 execution class EXC 3

- Welding of reinforcing steel in accordance with EN ISO 17660

- Conformity of the factory production control

- TÜV Austria cooperation and certification partner for welding and soldering, as well as for approvals by an accredited body

- ISO 9001

- Non-destructive testing in accordance with EN ISO 9712 for the VT, MT, PT, RT, UT methods by in-house testers

- Welding procedure qualification according to:

– EN ISO 17660-1:2006

– EN ISO 15614-1:2017+A1:2019, level 2

– EN ISO 15614-1:2017+A1:2019, level 2 and AD 2000 Merkblatt HP 2/1: 2021